Our capital controlled education system does not teach natural science and natural history nor the natural laws that govern biological systems that keep all life healthy!

“True law is right reason in agreement with nature; it is of universal application, unchanging and everlasting; it summons to duty by its commands, and averts from wrong-doing by its prohibitions. And it does not lay its commands or prohibitions upon good men in vain, though neither have any effect on the wicked. It is a sin to try to alter this law, nor is it allowable to attempt to repeal any part of it, and it is impossible to abolish it entirely” Marcus Tullius Cicero, De Re Publica (The Republic), book 3, paragraph 22; in De Re Publica, De Legibus, trans. Clinton W. Keyes (1943), p. 211.

“Not to know what happened before you were born is to be a child forever. For what is the time of a man, except it be interwoven with that memory of ancient things of a superior age?” – Marcus Tullius Cicero

Sadly, the education of lawmakers is grossly incomplete because they are not even trained in the scientific method.

“The CIA laundered money in the Olin Foundation between 1958 and 1966 but in 1967, the press uncovered the covert propaganda operation so the CIA folded that specific program. The Olin Foundation continued the strategy and certainly funded a lot of “beachheads.” Allan Bloom, Dinesh D’Souza, Harvey C. Mansfield, Samuel P. Huntington, John Yoo, John R. Lott Jr., and David Brock… (to name a few)

“Like an academic Johnny Appleseed, the Olin Foundation underwrote 83 percent of the costs for all Law and Economics programs in American law schools between the years 1985 and 1989… In all, by the time it closed its doors in 2005, the Olin Foundation had supported eleven separate programs at Harvard, burnishing the foundation’s name and ideas and proving that even the best-endowed American university would allow an outside, ideological group to build “beachheads,” so long as the project was properly packaged and funded.” – Dark Money page 105 & 107

(Of special note, a required course for all pre-law school student was taking the Principles of Reasoning. The textbook changed after the Olan Foundation took over majority funding for las schools across the US. Prior editions were called “The Principles of Reasoning and an Introduction into the Scientific Method.” The introduction to the scientific method was eliminated in later editions and replaced with a “free market” program. Our law makers, as a result, are completely scientifically illiterate.)

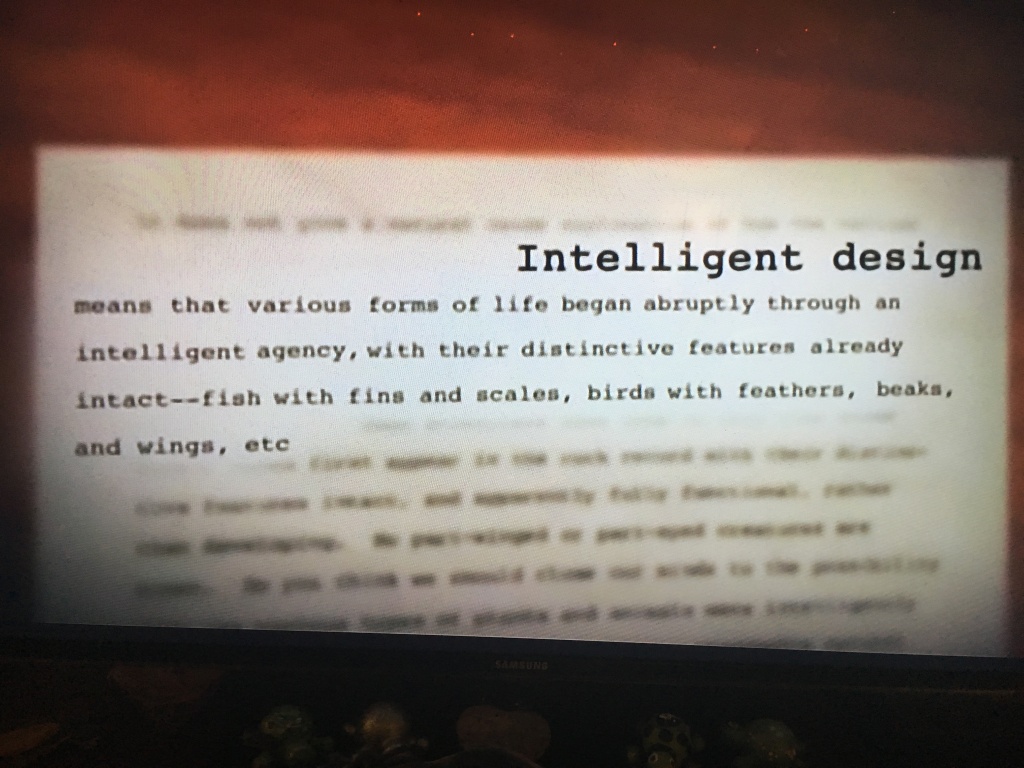

Enter “Intelligent Design” manufactured by CIA educated clergy and attorneys who have zero foundation of scientific knowledge..

Their Wedge Strategy has divided the workers and kept them from holding capital accountable for crimes against humanity and all life. The capital class has manufactured technologies and subjected the working class to unnatural selection and permanent destruction of the complexity of the natural biological systems of inheritance and has permanently altered the health of our species and all life!

There’s currently a huge capital funded CIA movement built off of lessons learned in manipulation of the masses.

Natural science has been deliberately removed from capital controlled education systems.

The biology textbooks in the United States are created by a CIA Catholic fascist. The Catholic Churches and the Fundamentalists Churches protect capital markets and systems.

CIA’s Use of Journalists and Clergy in Intelligence Operations

https://archive.org/details/ciasuseofjournal00unit_201611/page/n1/mode/2up

It’s important to see how capital manufactures right-wing fascism and it’s why their faithful believers will always be in the dark to the machinations of capital’s manufactured diseases and poverty. True believers can’t find truth because they believe in capital’s manufactured lies that distort biological realities.

Neil Shubin worked at the Field Museum studying and learning from the fossil collections. His office was right around the corner from my office in the library where he utilized geological science books to map out his expedition locations. His testimony was actually giving lawyers, the judge, and the reporters natural science lessons in this famous US court case. What is missing is a more comprehensive understanding of capital’s overall role in determining what science is disseminated in their education system.

(Notice this is now no longer available? That’s because capital is destroying natural science to protect themselves from accountability of their manufactured crimes against humanity. )

https://www.pbs.org/wgbh/nova/video/judgment-day-intelligent-design-on-trial/

t is still available to read the transcripts. The primary figures are important. Neil Shubin’s science lessons are edited even on P BS network program “Your Inner Fish” to protect capital’s synthetic Vitamin A market products..

“Recall when you treat the limb with retinoic acid, a form of vitamin A, you get a ZPA active on the opposite side. Guess what happens when you treat a limb with retinoic acid, then map where Sonic hedgehog is active? Sonic hedgehog is active on both sides–pinky and thumb–just as the ZPA does when it is treated with retinoic acid.

Knowing the structure of the chicken Sonic hedgehog gave other researchers the tools to look for it in everything else that has fingers, from frogs to humans. Every limbed animal has the Sonic hedgehog gene. And in every single animal we have studied, Sonic hedgehog is active in ZPA tissue. If Sonic hedgehog hadn’t turned on properly during the eight week of your own development, then you either would have extra fingers or your pinky and thumb would look alike. Occasionally, when things go wrong with Sonic hedgehog, the hand ends up looking like a broad paddle with as many as twelve fingers that all look alike.“

Evolution cannot be understood at all without an education in the many fields of biological sciences, and specifically, in genetics, epigenetic and microbiology sciences. Evolution is not a belief at all! The devoted Catholic (likely CIA Agent), Ken Miller is actually not very literate in the multiple fields of biology and claims that the reason critically important science lessons like explaining how RNA interference silences genes in development that causes congenital malformations (birth defects) is absent is because of the fundamentalist Christian movement. That’s a manufactured lie.

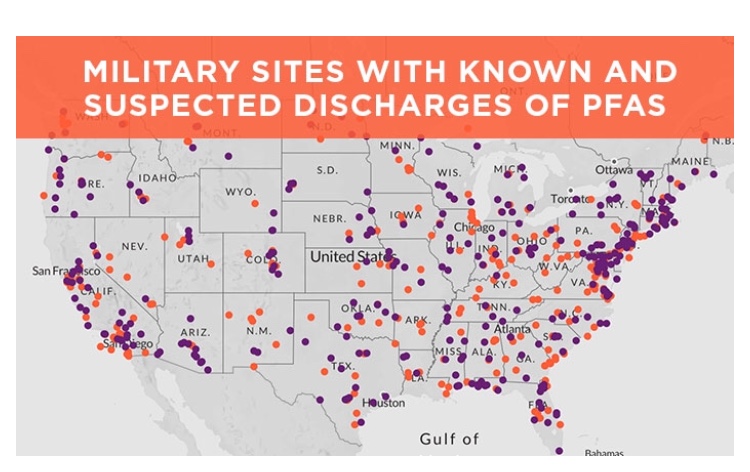

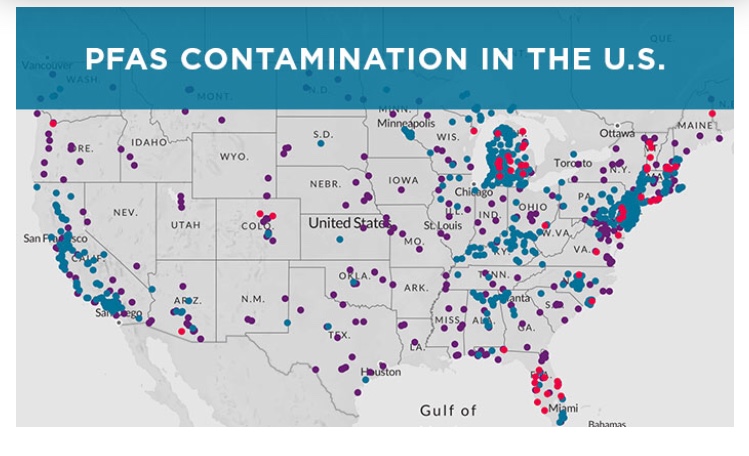

Judgement Day Intelligent Design on Trial was a court case set in Dover, Pennsylvania. DuPont headquarters is 35 times the size of the Pentagon and is in Pennsylvania as is the headquarters of Merck pharmaceuticals and Johnson & Johnson’s McNeil Pharmaceuticals. All located in Pennsylvania so it makes sense that they want the working class citizens of Pennsylvania to be completely illiterate in biological science so they can continue manufacturing their diseases and congenital malformations and hope citizens continue praying instead of mobilizing to protect their offspring from capital production that destroys the complex genetic and epigenetic and microbiome transfer inheritance system. They don’t want scientifically literate working class. (That would lead to important questions being asked about capital’s market systems and property control.)

Nazism was religious and created an ideology that vilified groups for extermination. The children born with Down Syndrome, autism, or all who did not conform to their rigid belief system were literally destroyed. In the case of Dr. Asperger, he and his pseudoscientific doctor colleagues created a classification system devoid of actual biology to determine the presence of a soul. Those without received experimentation and treatment.

These Nazi doctors practiced pseudoscience and they believed themselves as the intelligent designers ridding their nation of what was contaminating it and making it sick in order to restore its health.

There was no biological understanding or even evaluation of the complexity of the IG Farben technologies and their impacts on developing life.

A similar parallel in all western capital controlled nations that keep the fields of biological sciences separate from the hydrocarbon and radiation medical healthcare system. There is no searching for causes of illness and most of the biological fields are not taught in much complexity in field of medicine.

Buyer beware of another similar trend that capitalists are fueling right now.

NEIL SHUBIN: Darwin didn’t even know about molecular biology and DNA, yet that’s where some of the most profound evidence is being uncovered today. Think about that. That somebody in the 1800s made predictions that are being confirmed in molecular biology labs today. That’s a very profound statement of a very successful theory.

(Take special note of Kenneth R Miller’s ignoring Dr. Lynn Margulis, Dr, Rachel Carson, and Dr. Theo Colborn’s scientific discoveries and understandings? Completely absent from his biology textbooks across the US today? Neil Shubin teaches a multidimensional anatomy and physiology course at the University of Chicago that is still not in textbooks! He explained the genes that we share with all life like the sonic hedgehog gene that is critically important in the hand development of all life forms. Thalidomide victims understand what happens when the sonic hedgehog gene is silenced by RNA interference in development!)

Kenneth Miller is controlled by capital and protects capital markets by editing out the critically important natural science lessons from capital controlled education systems. Guessing he is CIA sponsored because he ignores much natural science and how capital technologies destroy those natural systems. Take note of the Rothschild attorney as well. Baron Rothschild certainly didn’t want the working class to understand that radium had the same chemistry as calcium and guessing that’s why his highly profitable radium based market products, including X-Ray technologies, are protected and not the working class being injuredby them.

KENNETH R. MILLER: Not a single observation, not a single experimental result, has ever emerged in 150 years that contradicts the general outlines of the theory of evolution. Any theory that can stand up to 150 years of contentious testing is a pretty darn good theory, and that’s what evolution is.

NARRATOR: And the deep understanding of evolution as proposed by Darwin has, with genetics, unlocked many of the secrets of life.

ROBERT PENNOCK (Michigan State University):It’s an explanatory framework within which all the rest of biology fits. It’s something that we use in practical biological applications: medicine, agriculture, industry. When you’re getting a flu vaccine—that really depended upon evolutionary knowledge. In many, many specific ways, evolution makes a practical difference. It’s not just something that happened in the past, evolution’s happening now.

(Notice how he explains how biology is utilized in capital manufactured systems and technologies and fails to distinguish natural science from capital’s use of biology to manufacture technologies and market products?

That’s not actually science but marketing of capital technologies and systems because Trade Secrets immediately identify pseudoscience by definition.)

NARRATOR: So if evolution has stood up to all this scrutiny, what about intelligent design? Does it play by the same rules?

KENNETH R. MILLER (Dramatization): If you invoke a non-natural cause, a spirit force or something like that, in your research, I have no way to test it.

WITOLD “VIC” WALCZAK (Dramatization): So supernatural causation is not considered part of science?

KENNETH R. MILLER: I’ve never made a secret of the fact that I’m a Roman Catholic, and a long tradition of scholarship in the Catholic Church has argued that truth is one, that science and religion should ultimately be in harmony. But that doesn’t make faith a scientific proposition. I think, as many religious people do, that faith and reason are both gifts from God. And if God is real, then faith and reason should complement each other rather than being in conflict.

(Comical that he’s outing himself as a CIA operative and he’s fighting another wing of a capital operation that puts itself by manufacturing a false pseudoscientific theory created by an “intelligent agent!” ![]()

If you are all wondering why Americans are so illiterate… it’s by capital manufactured design.

The CIA created Creationsim morphed into Intelligent Design and has morphed once again into Terrain Theory. A theory that claims DNA does not exist. Who do you think that serves?

NARRATOR: So how can scientists be so sure Darwin’s tree accurately represents the history of life on Earth?

As it turned out, the latest in a large body of evidence to refute intelligent design and support evolution was coming to light just as this case was unfolding.

NEIL SHUBIN: I remember thinking to myself, when all this was going on, “Wait’ll they get a look at this, because it’s just so beautiful.”

NARRATOR: Darwin believed that evidence for his idea of common ancestry would be unearthed in the form of transitional fossils. For example, if, over millions of years, fish gave rise to land animals, as evolutionary theory predicts, we should find fossils of extinct creatures that are part fish and part land animal.

In 1999, paleontologist Neil Shubin and his colleagues set out to find just such a creature.

NEIL SHUBIN: What evolution enables us to do is to make specific predictions about what we should find in the fossil record. The prediction in this case is clear-cut. That is, if we go to rocks of the right age, and the rocks of the right type, we should find transitions between two great forms of life, between fish and amphibian.

NARRATOR: Many scientists think life began in the water, at least three and a half billion years ago. More recently, about 375 million years ago, the tree of life branched as primitive fish evolved into amphibians, such as today’s frogs and salamanders, which live part of their lives on land.

Armed with this prediction, Shubin and his colleagues organized an expedition to one of the most desolate places on Earth, the Canadian Arctic, about 500 miles from the North Pole, where rocks of just the right age are exposed. Here, they hoped to fill a gap in the branch of the evolutionary tree that leads from primitive fish to animals with four limbs, or “tetrapods,” by finding a fossil of an animal that shared characteristics of both.

But after three summers of digging through hundreds of tons of rock in this harsh environment, they had found little of interest. They returned the next year for one last try.

NEIL SHUBIN: Money was running out. This was it. We were told this was our last year up there. And then, in 2004, in the third day of the season, a colleague of mine was removing rock and discovered a little snout sticking out the side of the cliff, just exactly like this. And he removed more rock and more rock and more rock, and it became clear this was a snout of a flat-headed animal. And that’s when we knew. Flat-headed animal at 375-million years old? This is going to be something interesting.

NARRATOR: They called it Tiktaalik, which means “large, fresh water fish,” in the language of the local Inuit people. And it’s one of the most vivid transitional fossils ever discovered, showing how land animals evolved from primitive fish.

NEIL SHUBIN: Over here you have a fish of about 380-million years old. And, just like any good fish, it has scales on its back and fins. You compare that to an amphibian, and you find a creature that doesn’t have scales, and it’s modified the fins to become limbs, arms and legs. And the head’s very different. It has a flat head with eyes on top and a neck.

What we see when we look at the fossil record, at rocks of just the right age, is a creature like Tiktaalik. Just like a fish, it has scales on its back, and fins. You can see the fin webbing here. Yet when we look at the head, you see something very different. You see a very amphibian-like thing, with a flat head, with eyes on top. It gets even better when we take the fin apart. When we look inside the fin, as in this cast here, what you’ll see is bones that compare to our shoulder, elbow, even parts of the wrist—bone for bone. So you have a fish, at just the right time in the history of life, that has characteristics of amphibians and primitive fish. It’s a mix.

NARRATOR: And just as evolutionary theory predicts, Tiktaalik suggests a tree of life, with one species giving rise to another over millions of years.

The discovery of Tiktaalik was still being written up at the time of the trial, so it couldn’t be used as evidence. But Shubin’s colleague, paleontologist Kevin Padian, showed the judge examples of other fossils with transitional features that support Darwin’s tree of life.

KEVIN PADIAN: My testimony in the trial was basically taking a day and showing the judge how we do our work and what the evidence is.

NARRATOR: How dinosaurs evolved into birds, as seen in creatures like Archaeopteryx which has a long tail and teeth like a dinosaur, but feathers just like a modern bird. How ancestors of modern reptiles evolved into creatures now extinct that share a common ancestor with mammals. And, how, surprisingly, whales evolved from large land animals that returned to the water.

KEVIN PADIAN: And where the Pandas book says we can’t go from A to B, there are no fossils and we don’t know how to study them, actually, we’ve gone from A to B and to C, D, E, F and G. We have the fossils; we have the transitional features; we have the ways of analyzing them with many different lines of evidence. And we’re looking for the picture that accounts for the most lines of objective evidence.

NARRATOR: With each fossil, Padian refuted Pandas claim that different life forms appear suddenly, by showing how fossils of extinct organisms bridge the gaps between species, resulting in a picture of gradual evolution, just as Darwin proposed.

KEVIN PADIAN: The reporters in the courtroom were just amazed that we knew all this stuff. And how come they hadn’t learned about this stuff before? And the reason is it’s not in textbooks because the creationists fight so hard to keep it out. That’s been a big influence…

(Wrong! Capitalists deliberately omit natural science and history from their education and media systems!)

NEIL SHUBIN: Science is about discovering the unknown, what we don’t know. I don’t focus on what we know as a scientist. I want to find new things that tell me about what I don’t know.

(Neil is an outstanding natural science teacher!)

NARRATOR: As the plaintiffs testified, that quest to investigate the unknown has led to the discovery of some of the strongest evidence for evolution.

Darwin was convinced that species evolve over time, through natural selection acting on inherited traits. But he had no idea how those traits arose or how they were passed from generation to generation.

When 20th century scientists discovered the role DNA plays in heredity, they founded a new science, called “genetics,” that put Darwin’s theory to the test.

Virtually every cell in every living thing contains chromosomes, which are made of densely packed strands of DNA that function as a blueprint of the individual organism’s characteristics. During reproduction, chromosomes from each parent replicate and shuffle their parts to produce new chromosomes. Then, each parent passes chromosomes to offspring. But the process is imperfect. Along the way, DNA is subject to random mutations, or mistakes, giving each offspring its own unique blueprint. Sometimes this produces characteristics in offspring that are benign. Other times it produces harmful characteristics, like a misshapen wing. But occasionally, the process gives rise to a beneficial trait. For example, a butterfly whose coloration mimics another species of butterfly that tastes bad to birds.

About a hundred years after Darwin proposed that natural selection acts on new traits appearing in a population, genetics revealed the biological mechanism that gives rise to those traits in the first place.

KENNETH R. MILLER (Dramatization): And therefore you could say that when modern genetics came into being, everything in Darwin’s theory was at risk, could have been overturned if it turned out to contradict the essential elements of evolutionary theory, but it didn’t contradict them, it confirmed them in great detail.

NARRATOR: And, as Miller would testify, a genetics paper published less than a year before the trial had confirmed what has long been the most inflammatory part of Darwin’s theory, the common ancestry of humans and apes.

That paper explored a curious discrepancy in our chromosomes. The cells of all great apes, like chimpanzees, gorillas and orangutans, contain 24 pairs of chromosomes. If humans share a common ancestor with apes, you’d expect us to have the same number. But surprisingly, human cells contain only 23 pairs.

KENNETH R. MILLER (Dramatization): The question is, if evolution is right about this common ancestry idea, where did the chromosome go? Well, evolution makes a testable prediction, and that is that somewhere in the human genome, we ought to be able to find a piece of Scotch tape holding together two chromosomes, so that our 24 pairs…two of them were pasted together to form just 23. And if we can’t find that, then the hypothesis of common ancestry is wrong and evolution is mistaken. Next slide.

NARRATOR: To solve this riddle for the court, Miller would show how scientists discovered traces of our evolutionary past buried in the very structure of a chromosome carried by all humans.

Typically, on the ends of every chromosome, you should find special genetic markers, or sequences of DNA called “telomeres.” And in their middles, you should find different genetic markers called “centromeres.” But if a mutation occurred in the past, causing two pairs of chromosomes to fuse, we should find evidence in those genetic markers: telomeres not only at the ends of the new chromosome, but also at their middles, and not one, but two centromeres. Finding a structure like this in our chromosomes would explain why humans have one pair fewer than the great apes.

KENNETH R. MILLER (Dramatization): And if we can’t find that, then evolution is in trouble. Next slide.

Lo and behold, the answer is in Chromosome Number 2. All of the marks of the fusion of those chromosomes predicted by common descent and evolution, all those marks are present on human Chromosome Number 2.

So the case is closed in a most beautiful way. And that is the prediction of evolution of common ancestry is fulfilled by that lead pipe evidence that you see here, in terms of tying everything together, that our chromosome formed by the fusion from our common ancestor is Chromosome Number 2. Evolution has made a testable prediction and it has passed.

WITOLD “VIC” WALCZAK (Dramatization): So modern genetics and molecular biology actually support evolutionary theory?

KENNETH R. MILLER (Dramatization): They support it in great detail. And the closer we can get to looking at the details of the human genome, the more powerful the evidence has become.

NEIL SHUBIN: Darwin didn’t even know about molecular biology and DNA, yet that’s where some of the most profound evidence is being uncovered today. Think about that. That somebody in the 1800s made predictions that are being confirmed in molecular biology labs today. That’s a very profound statement of a very successful theory.

Published: 07 April 2005

Generation and annotation of the DNA sequences of human chromosomes 2 and 4

https://www.nature.com/articles/nature03466

KENNETH R. MILLER: Not a single observation, not a single experimental result, has ever emerged in 150 years that contradicts the general outlines of the theory of evolution. Any theory that can stand up to 150 years of contentious testing is a pretty darn good theory, and that’s what evolution is.

NARRATOR: And the deep understanding of evolution as proposed by Darwin has, with genetics, unlocked many of the secrets of life.

ROBERT PENNOCK (Michigan State University):It’s an explanatory framework within which all the rest of biology fits. It’s something that we use in practical biological applications: medicine, agriculture, industry. When you’re getting a flu vaccine—that really depended upon evolutionary knowledge. In many, many specific ways, evolution makes a practical difference. It’s not just something that happened in the past, evolution’s happening now.

NARRATOR: So if evolution has stood up to all this scrutiny, what about intelligent design? Does it play by the same rules?

KENNETH R. MILLER (Dramatization): If you invoke a non-natural cause, a spirit force or something like that, in your research, I have no way to test it.

WITOLD “VIC” WALCZAK (Dramatization): So supernatural causation is not considered part of science?

KENNETH R. MILLER (Dramatization): Yeah. I hesitate to beg the patience of the Court with this, but being a Boston Red Sox fan, I can’t resist it. One might say, for example, that the reason the Boston Red Sox were able to come back from three games down against the New York Yankees was because God was tired of George Steinbrenner and wanted to see the Red Sox win. In my part of the country, you’d be surprised how many people think that’s a perfectly reasonable explanation for what happened last year. And you know what? It could be true, but it certainly wouldn’t be science. It’s not scientific, and it’s certainly not something we can test.

EUGENIE C. SCOTT: The fundamental problem with intelligent design is that you can’t use it to explain the natural world. It’s essentially a negative argument. It says, “Evolution doesn’t work, therefore the designer did it. Evolution doesn’t work, therefore we win by default.”

But when you ask them, “What does intelligent design tell you about nature? Does it tell you what the designer did? Does it tell you what the designer used to design something with? Does it tell you what purpose the designer had for designing something? Does it tell you when the designer did it? Why the designer did it?” It doesn’t tell you anything like that. Basically, it’s a negative argument. And you can’t build a science on a negative argument

Looks like capital learned important lessons from the trial when they manufactured their CIA sponsored “Terrain Theory” that claims DNA and viruses don’t even exist…

What confuses me is how many have no problem claiming the field of genetics and epigenetics exist but viruses (whether they are DNA or RNA with their capsid protein coating) do not exist… how does that work?

You should watch Judgment Day Intelligent Design on Trial. The CIA intelligent agents in our churches have modified their wedge strategy to call actual biological science that studies natural systems pseudoscience

No longer available on P BS…

CIA’s Use of Journalists and Clergy in Intelligence Operations

https://archive.org/…/ciasuseofjournal…/page/n1/mode/2up

TerriaIn Theory is as capital manufactured as Germ Theory.

Not a scientific theory rooted in biological science.

Intelligent Design is actually Creationism and not science at all. It tries to disguise itself as science but it’s only a capital manufactured theory to sell their capital natural market products and treatments

They literally cut and pasted in intelligent design to replace creationism which was presented at trial in discovery documents.

What’s important to note is that the judge called it science class and he was appointed by Bush who promoted intelligent design. The judge, lawyers and the journalists were shocked by how much they learned about natural science and genetic discoveries and asked why they’ve never heard any of the information presented at court?

The man who writes the biology textbook for our public education system said he is a devout Catholic and left out the chromosome 23 evidence and more because creationists wouldn’t allow it.

That’s a lie. Capital can’t have the workers educated in biological science, genetics, and epigenetics because then they would not buy most of capital’s systems and consumer products.

Capital needs cult believers not those who ask critically important science questions about the technologies they are manufacturing..

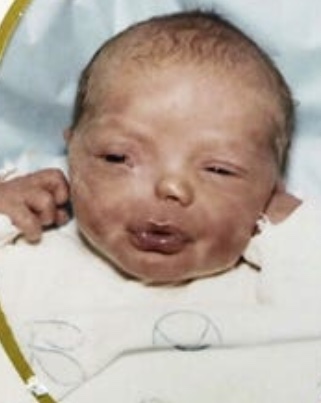

Neil Shubin’s book Your Inner Fish should be required reading right now. It will never be in high school biology classes and pregnant women still do not understand how synthetic vitamin A causes a specific birth defect either. P BS edited that part out of their series to protect those capital markets.

Example

errain Theory is like Germ Theory (a manufactured theory and not a scientific theory at all) Terrain Theory is utilized to sell capital’s “natural market treatments and systems” many of those natural manufactured capital market cures are as loaded with heavy metals as the hydrocarbon technology markets. Lead and mercury contaminated industrial equipment is not healthy by manufactured design and the superfund sites that sicken entire communities of people are as ignored by capital’s terrain theorists as the former germ theorist cultists..

Germ Theory ignored Symbiontism and The Origin of Species by Ivan Emmanuel Wallin in 1927 (as the Terrain theorists ignore Dr. Lynn Margulis today)… which provided a then marginalized snd censored scientific theory that the mitochondria was actually a prokaryotic cell that evolved in biological operations in eukaryotic cells…

Germ theory was a manufactured theory to promote and sell capital’s hydrocarbon and radiation technology markets and systems..

Dr. Lynn Margulis would wIn the National Medal of Science by revisiting that theory and provide the most comprehensive scientific evidence that Wallin’s theory was true.

Terrain Theorists of today ignore a foundation of biological evolutionary knowledge.

“Before Lynn Margulis, scientists believed that evolution solely occurred from random gene mutations. In the late 1960s, Margulis began to develop her theory that would undercut traditional, Darwinian views of evolution.

While Margulis did not argue against the role of random mutations in evolution, she put forth the notion that the foundation of evolution is two organisms of different species benefitting through coming together and synchronously reproducing. She contended that evolution had a jump start with the help of unicellular organisms joining to form hybrids, and, over generations, leading to multicellular organisms with more complex DNA. Margulis supported this theory through showing mitochondria have their own nuclei with different genetic makeup than their cell’s DNA. Her theory subverted traditional theories of evolution, suggesting that evolution has it roots in symbiosis, rather mutations occurring within a single organism’s genome.

Although her theory would prove to be critical to studying evolution, it was considered controversial and even ridiculed at the time. The manuscript containing Margulis’s theory was rejected fifteen times before it was finally published in 1967. Margulis’s revised version of her thesis, titled “Symbiosis in Cell Evolution”, while still controversial when published, is today widely acknowledged as evolutionary doctrine.“

The CIA’s evolved wedge strategy continues to protect capitalists from being held accountable for creating the most biologically destructive markets that do the opposite of serving and protecting the working class.

Like their radium market technologies! When Marie Currie discovered radium in 1901, she also discovered that radium has the same chemistry as calcium.

Didn’t stop capitalists from promoting those pioneering markets or disclosing the harm. The radium girls who died from the most horrific suffering were vilified and physiologists paid by capital puppets claimed they were loose women who died of syphilis…

They are still utilizing unnecessary radium based dyes in surgical operations and they sure as hell don’t get informed consent from patients about the biological injuries they cause.

Upton Sinclair said that Fascism was capitalism with murder.

Well capitalists have been getting away with mass manufacturing murder for centuries because the working class fail to understand the system and the technologies they utilize to profit off of their exploitation and destruction.

“One of the few survivors of the asteroid impact 65 million years ago was a small, furry, shrew-like creature that lived in underground burrows and only ventured out at night, when predators weren’t active. The critter—already the product of some 100 million years of evolution—looked like a modern mammal, with body hair and mammary glands, except for one tiny detail: according to a recent genetic study, it didn’t have a placenta. And its kind might never have evolved one if not for a chance encounter with a retrovirus.

Unlike most viruses, which infect, replicate, and then leave their host, retroviruses elbow their way into their host’s genome where they are copied and passed on to daughter cells for the life of the host. This retrovirus, however, managed to sneak its way into one of our ancestor’s sperm or egg cells, able to be passed on to every cell in every subsequent generation. Virus and host had become one.”

https://www.pbs.org/…/article/endogenous-retroviruses/

“Cullen said that this discovery could have implications for xenografts, the untested practice of transplanting animal organs, such as kidneys, into humans. With any transplant, the recipients receive not only the organ, but also any viruses that may be living in its cells. In the case of animal-to-human transplants, the procedure brings genetic material from two different species into close contact.“

https://www.hhmi.org/news/human-genome-bears-virus-related-hiv-1

The mitochondria in every single one of our cells is actually a prokaryotic (microbe capitalist’s call them “germs”) cell evolved in our eukaryotic cells. Manufacturers call all microbes (whether they are bacteria, protoctists, fungi and the fourth type of microscopic being are called viruses which are not made up of cells and only some of which are disease-causing agents that are not made of cells but are genetic material (DNA or RNA) wrapped inside a protein coat. They are able to enter into and take over normal operations of other cells. Viruses can enter the cells of bacteria, protoctists, fungi, plants, and animals. Many have lead to evolutionary changes and new species through symbiosis.

Now think about all those anti-microbial manufactured products capitalists have manufactured? They, by their definition, then destroy the mitochondria in our eukaryotic cellular systems. Cellular health is dependent upon the health of the mitochondria..

Trying to teach those who don’t “believe” in viruses is the equivalent of trying to teach geological science and history and the fossil record to someone who believes the earth is only 5000 years old…

The CIA’s “wedge strategy” has many pseudoscientists working very hard right now to manufacture working class division and to create deliberate blindness to protect capital’s markets and their systems and technologies they’ve designed to enrich themselves and they are not actually intelligent at all. They lack the comprehensive foundation to even be considered “intelligent.”

The capital ”Counci of Gods” as they called themselves during their WWII reign, have created hell for our children here and abroad by all that they have manufactured and they certainly don’t want to be held accountable by the working class for all that they’ve exploited and destroyed.

The truly sad reality is that many scientists bought Capital’s last manufactured war against a retrovirus with so little thought about the market technology product and with little understanding at all…

They missed some critically important science lessons and capital history lessons themselves.

Questioning authority is rule number 1!

Of course the “Covid vaxxine” alters DNA!

The end of the chromosome is a telomere and an RNA machine…

To understand the science of RNA you’d automatically understand how it would, of course alter DNA!

It’s about as absurd to say that radium, which has the same chemistry as calcium, would do nothing to alter bones…

“Because a scientist doesn’t just look at things and make up his mind. A scientist interrogates the system. You have to do an experiment to probe and answer important questions.” – Dr. Thomas R. Cech (was awarded the 1989 Nobel Prize in Chemistry for his discovery of the catalytic properties of RNA.)

(Lecture 1 on the Double Life of RNA: Catalysis, Chemical and Biochemical)

Lecture 1

Catalysis, Chemical and Biochemical

Lecture 2

RNA as an Enzyme: Discovery, Origins of Life

Lecture 3

How to Accelerate a Reaction 100,000,000,000 Times Using only RNA

Lecture 4

Life at the End of the Chromosome: Another RNA Machine

“The last thing we would want chromosomes doing would be to fold up and catalyze their own cleavage or rearrangement in an uncontrolled way!” – Dr. Thomas Cech, PhD

And that is precisely what many capitalist munition and pharmaceutical technologies do!

Congenital and infant leukaemia are often associated with rearrangements of the MLL gene at chromosome 11q23. Several substances have been examined for their potential to cross the placental barrier and to induce such a chromosomal break at 11q23/MLL.

Here we extend the list of drugs capable of cleaving the MLL gene, at least when cells are exposed in culture. Together with a rather unusual case history, our experimental data shed some light on the generation of congenital leukaemia and may help to prevent some of the fatal cases of this disease…

The infant died 48 hours after birth from multiorgan failure. Apart from the severe brain damage already diagnosed by ultrasound, the autopsy showed diffuse infiltration of lungs, liver, spleen, and cutis.”

None of those drugs or pesticides have been removed from capital markets and women are not educated at all about even the biological complexity of their own bodies and how life evolved.

The scientific theory of evolution is not taught through genetics and epigenetics! Hell, they don’t even teach geological history and the fossil record either!

The CIA created “Intelligent Design” that’s an evolved pseudoscience since the Pennsylvania Trial so workers are clueless about how they and their communities and their children are destroyed by capital technologies.

Well, the CIA “Wedge Strategy” certainly paid off!

Capital protects their market interests not life. They created a system that exploits and destroys our children.